Image

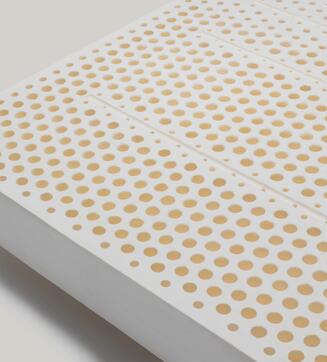

DUNLOP

One of the most popular and energy-efficient methods to produce high-quality latex foam is the Dunlop method. With this process – using conventional steam heating and drying methods – we manufacture blocks, pillows and sheets.

The Dunlop process

One of the most popular methods to produce high-quality latex.

Preparing the latex formulation

Liquid latex is mixed with a small amount of vulcanisation agents such as soaps and antioxidants.

Pouring

The latex formulation is foamed up with air by a mechanical mixer and poured into aluminium moulds or onto a continuous belt.

Vulcanisation

The foamed-up latex enters an industrial steam oven, where it is vulcanised at 100 to 110 °C for one hour.

Washing

Once vulcanised, the latex is washed, to rinse off any residual soaps or vulcanisation agents.

Drying

The washed latex foam goes straight into an industrial oven to remove excess moisture.

Inspection

The final product is inspected for quality control and shipped off to provide the ultimate comfort we all deserve.

Image

Our solutions

Latex is used to produce quality pillows, blocks and sheets. It is a versatile material that embraces and supports, guaranteeing a durable and sustainable sleeping experience.

Image

Image

Image