Image

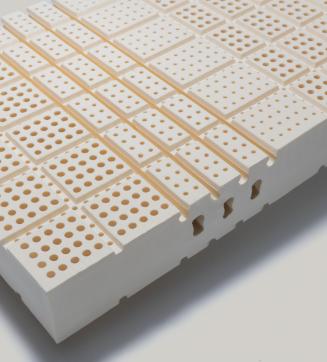

TALALAY

Breathable, supportive and luxurious: our original Talalay latex is engineered for the ultimate comfort of your clients. It is a unique material that lifts your body, relaxes your muscles and relieves tension.

The Talalay process

Talalay process creates the most consistent and breathable latex available on the market.

Formulating

We mix together liquid latex and raw materials for a perfect balance, proven superior in the industry.

Moulding

The mixture is transferred to the pressroom where it is aerated and injected into an aluminium pin core mould. This results in a unique cell structure.

Dispersing

After sealing the mould, a vacuum is used to pull and fill the mould with liquid latex. This process allows for full control of the consistency and firmness of the product.

Freezing

The formula is flash frozen at a temperature of -30 °C. This prevents particles from settling and locks in Talalay’s unique cell structure.

Gelling

The latex is heated to 104 °C, transforming it into a solid state.

Washing

Once it has reached a solid state, each Talalay core and pillow undergoes a 5-stage wash process. This way we ensure a clean and healthy product.

Vulcanisation

Any residual moisture is removed by vulcanisation, completing the curing process.

Testing

Once dry, each product undergoes a 9-point firmness consistency test and infrared technology scan.

Image

Our solutions

Latex is used to produce quality pillows, blocks and sheets. It is a versatile material that embraces and supports, guaranteeing a durable and sustainable sleeping experience.

Image

Image

Image